Understanding Coolants in CNC Machines

Admin • September 13, 2018

Machining using Computer Numerical Control (CNC) technology has numerous uses in manufacturing and fabrication applications. Computer-controlled machining is especially useful in settings that require production of large quantities of fabricated items.

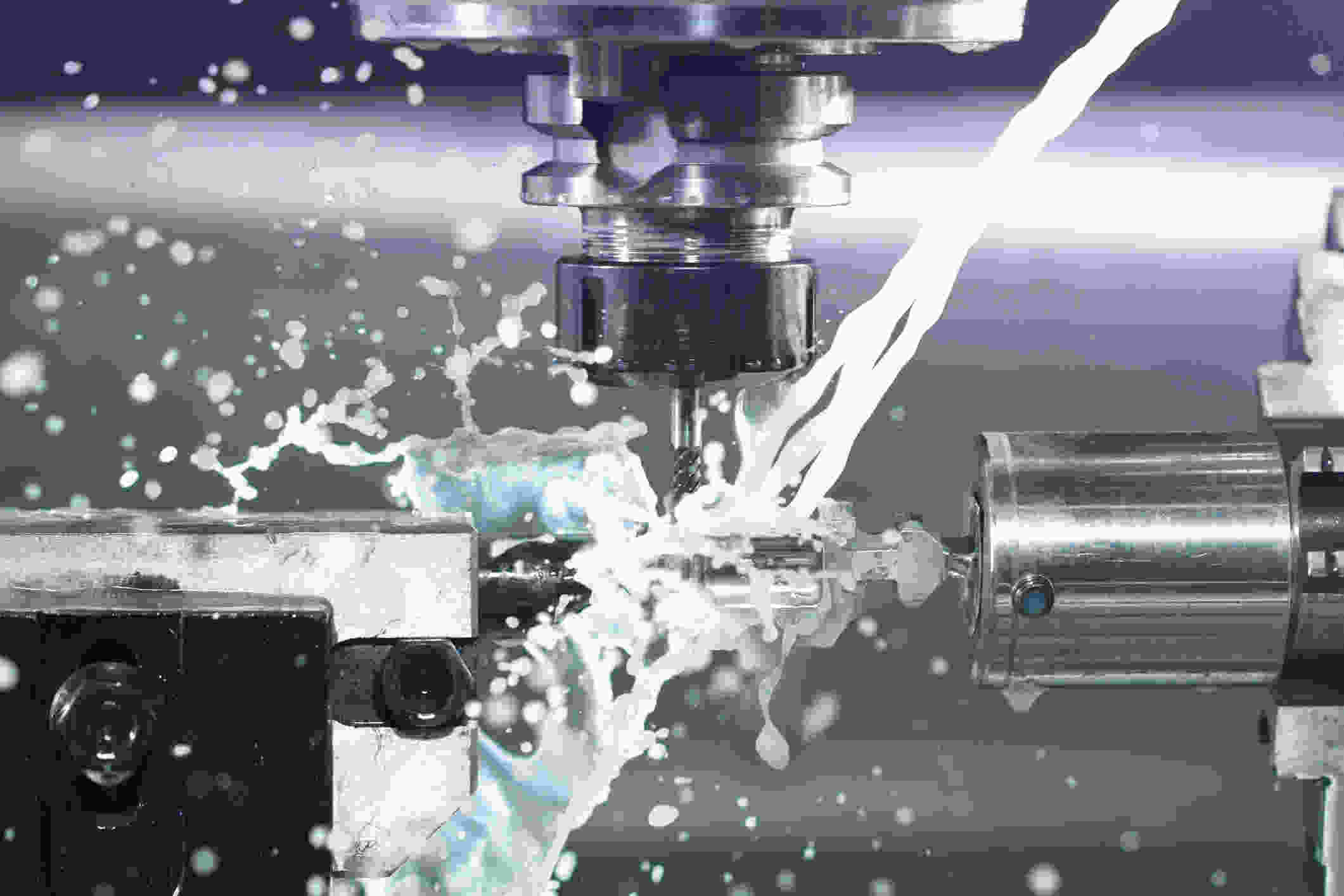

Coolant is one of the most important components of the machining process and plays a crucial role in prolonging the machine's life. Problems with the coolant system can result in machining bottlenecks, poor product quality, and costly downtimes.

Read on to learn more about coolant systems in CNC machines.

Basics of Machining Coolant

Coolant, also known as cutting fluid, is a type of lubricant that aids a CNC machine to easily cut materials such as metals, fiberglass, and high-density plastics among others.

When an operator uses the machine at low cutting speeds, the coolant helps to lubricate the cutting process. At high cutting speeds, the coolant cools the workpiece. Operators also apply coolant to keep the workspace free of the particles and debris coming from the workpiece the operator is cutting.

Other uses of coolant in machining include:

- Protecting the machine against corrosion

- Cooling hot surfaces to ensure safe handling of the machine and the workpiece

- Improving machine life

- Protecting the workpiece from deforming due to intense heat

In some applications, using the right type of cutting fluid can also aid in achieving high-quality finishes to meet client needs.

Types of Machining Coolant

Machining coolants fall under four categories — synthetic fluids, semi-synthetic fluids, soluble oils, and straight oils.

Synthetic Fluids

Synthetic fluids contain organic and inorganic alkaline ingredients instead of petroleum or mineral oils. These types of cutting fluids protect the machined workpiece against corrosion and have superior cooling properties.

Semi-Synthetic Fluids

Semi-synthetic fluids contain synthetic fluids and soluble oils. CNC machine operators use semi-synthetic fluids for their good heat-transfer properties.

Soluble Oils

Soluble oils consist of a mineral oil base and emulsion. Operators typically mix soluble oils with water to make the most of the fluid's heat transfer properties. Soluble oils are the most affordable and widely used coolants in machining.

Straight Oils

Straight oils are not usually diluted in water and primarily consist of petroleum or a mineral oil base. Straight oils also contain other lubricating elements such as vegetable fats and oils. Straight oils are great lubricants but do not work too well to cool machines or workpieces.

Types of Machining Coolant Systems

Operators use different coolant systems to apply cutting fluid to the workpiece and machine. A coolant system is a machine attached to a CNC tool to pump fluids to cool and lubricate workpieces and cutting machines.

Some common coolant systems include:

Flooding systems:

This system pours large quantities of coolant on the workpiece and machine surface. Flooding helps with debris management during the machining process.

Jetting systems:

The jet coolant system releases cutting fluid at a high pressure. The fluid is directed toward the cutting edge for better lubrication and cooling.

Misting systems:

Mist coolant systems release fluid that is atomized into small particles. This way, the coolant appears like a fog or mist when sprayed to the workpiece. Misting systems deliver better lubrication especially in high-speed applications.

Different applications will require the use of different coolant systems depending on the qualities of the workpiece, the type of CNC machine used, and the project goals.

The precision and efficiency that CNC machining delivers would not be possible without using the right coolant. Proper maintenance is necessary to keep coolant systems and CNC machines in great shape.

At Quad Fluid Dynamics, Inc.,

we have the skills and tools to rebuild various components of CNC machines, including coolant systems. Call us today if you have a question or any issues with your CNC machine.

Hydraulic pumps are quickly becoming an industry standard in industrial machinery. Continue reading to learn about the benefits of hydraulic pumps.

Custom hydraulic systems are used across a multitude of different fields and functions. Read on to learn more about the endless possibilities.

Hydraulic pumps are important. Dive into the common causes of hydraulic pump failures and explore effective solutions to keep your systems running smoothly.

Follow this quick guide to learn some of the best methods for determining exactly what hydraulic part you need and how to access those parts quickly.

Like any other machinery, hydraulic pumps need routine servicing to function efficiently. Learn how to drain and clean your hydraulic pump's reservoir.

At the heart of hydraulic systems lies hydraulic fluid, a critical component that enables the transmission of force and motion. Read to learn more.

How should you decide when to rebuild or repair your hydraulic system? Read this blog to learn the differences between the restoration methods.