4 Types of CNC Machine Repairs to Improve Drilling Efficiency

CNC machines can create sophisticated drilling and milling patterns. Whether you are in the manufacturing, mining, or automotive space, having a functional CNC machine should be a top priority for your business.

Sometimes, all you need is a simple adjustment to get your machines running more smoothly and efficiently. Discover four types of repairs that will increase drilling and milling accuracy to produce high-quality products.

1. Replace Your Control Valves

The control valve on your CNC machine is useful for regulating air pressure. If your valves work correctly, you can create precise cavities on your material for downstream manufacturing processes. Valves are one of the most common CNC machine repairs, and they are necessary for many jobs that require drilling. Even a small issue with valve performance could affect the range of motion in your equipment.

You can tell if your drill needs a new control valve by checking for dirt and low fluid levels. Dirt in your drilling equipment will lead to subpar results when working with hard materials such as wood, metal, or concrete. If your valves do not create an airtight seal while drilling, consider replacing them.

2. Check Your Hydraulic Power Unit Assembly

The hydraulic unit supplies power to the drill head and feed system during drilling. If this component doesn’t function correctly, it can cause inaccurate hole placement and poor-quality products.

You can test if your hydraulic power unit works correctly by checking the oil levels. If you notice low oil or dirt in your machine's oil supply, consider repairing the hydraulic unit. A faulty hydraulic assembly in your CNC machine could also result in low drill speeds.

Furthermore, dirty oil may interfere with the movement of your drill heads and reduce drilling accuracy.

3. Replace Dull Drill bits

The drill bit is the cornerstone of your CNC machine. Drill bits cut through your raw material, creating precise patterns and designs. Therefore, keeping your drill bit in good condition should be a top priority.

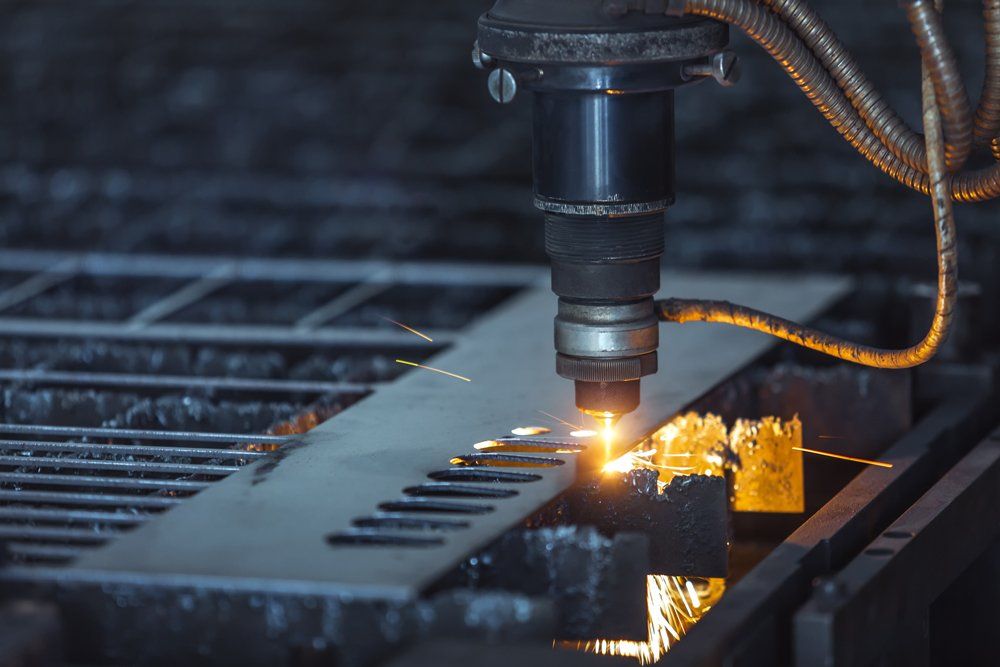

If your drill bit is not sharp, it will take longer to make a hole and cause inaccurate placement. A dull drill bit may also cause excessive wear on your CNC machine. One way to test if your drill bit is sharp is by looking at the sparks it produces.

Dull bits will produce little to no sparks, while a sharp bit will create bright sparks when it comes into contact with the material you are drilling. If your drill bit is underperforming, consider sharpening or replacing it.

4. Check Your Spindle Rotation

The spindle holds and rotates your drill bit, resulting in accurate cuts across your target material. If the spindle does not rotate correctly, you may notice excessive vibrations that affect drilling accuracy.

You have an easy way to check if your spindle works. A healthy spindle should make a humming noise, while a faulty spindle will produce a grinding sound.

A humming sound indicates that your spindle is guiding the drill bit, creating proper friction on your target material. Grinding noises are a sign that the drill bit is not firmly in place. If you notice drilling issues in your spindle and drill bit assembly, consider inspecting these components for damages.

CNC machines are essential tools for drilling and milling raw materials. Therefore, keeping up with repairs will improve efficiency and reduce waste. Quad Fluid Dynamics, Inc., offers a wide range of CNC repairs, rebuilds, and component upgrades. In addition, we customize the repair process to suit your specific needs. Ready to keep your CNC machine running smoothly?

Contact us today. We look forward to speaking with you.